Retrofitting

Retrofitting refers to the upgradation or improvement of existing toilet containment systems such as single pit latrines and septic tank–based toilets. In many rural areas, toilets already exist but are poorly designed or not suitable for safe fecal sludge management. Retrofitting is therefore an important approach to ensure that these existing systems function safely and support proper FSM.

Provisions for retrofitting toilets:

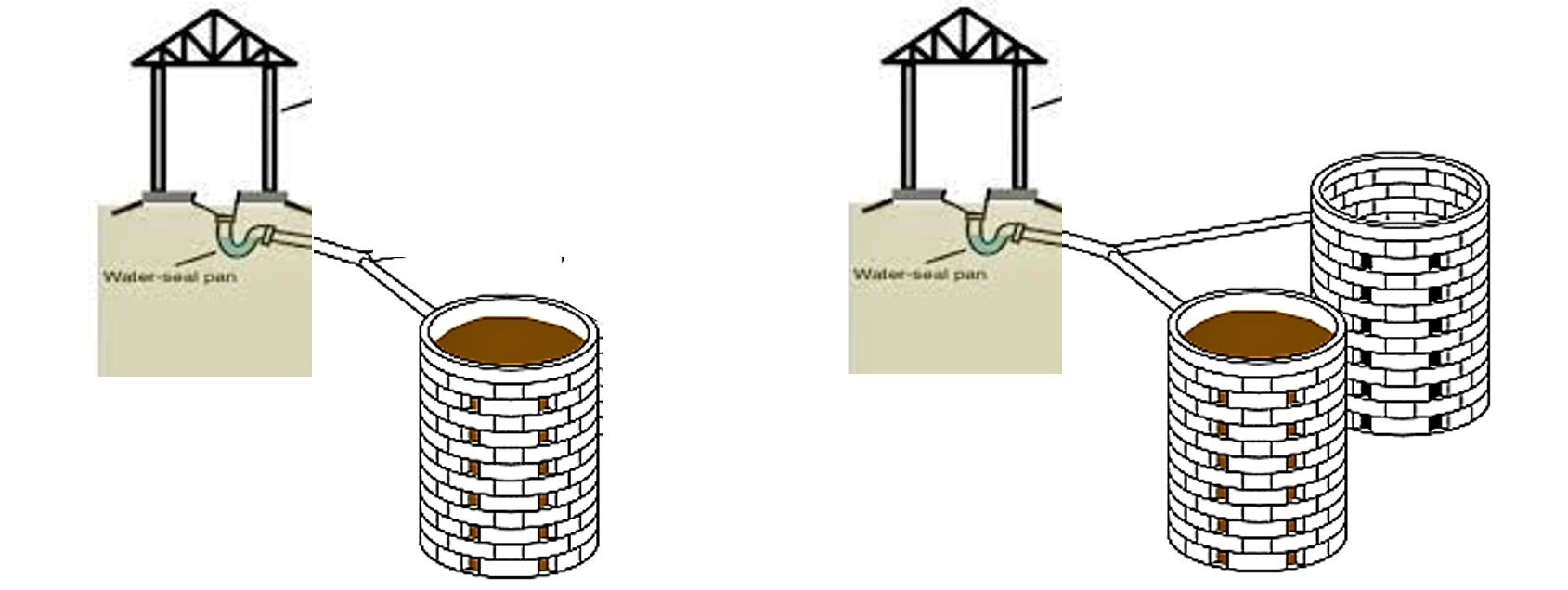

- Converting single pit latrines to twin pit, by adding an additional pit

- Correcting defective septic tanks (e.g. adding the chamber separation wall, sealing the bottom, etc.)

- Improving twin pits (e.g. ensuring functional junction chamber, honeycombing or perforations in pit wall, adequate distance between pits, safe distance from water sources, etc.)

- Installation/retrofitting of alternative twin pit diversion mechanisms which are easy and safe to install and use, for example SATO V-trap connection system

- Improving technologies and replacing leach-pit latrines with appropriate technologies in challenging geographies such as high-water table, rocky areas, etc. (example bio toilets, composting toilets, raised toilets, etc.)

Challenges:

- Un-availability of land at households, acceptance by households, expenses for reconstruction, etc., with this approach

Note: Retrofitting is not suitable as treatment approach in urban areas.